Our Certified Peptide Synthesis Lab is specifically designed and operated to permit the custom synthesis of peptides in accordance with defined procedures and under prescribed laboratory conditions. The facility is environmentally controlled and uses validated instrumentation, including state-of-the-art HPLC systems interfaced with the Empower Chromatography Manager, for peptide purifications and purity assessments. Peptides are provided with a Certificate of Analysis of product purity specifications, and can be made available packaged aseptically in sealed vials containing designated mass quantities.The Certified Peptide Synthesis Lab can also assist investigators in identifying and establishing subcontracts with outside companies to acquire further testing (e.g., sterility; endotoxin; and various analytical assays, including peptide content, moisture content, and optical rotation) of our certified peptide products as may be required in support of the conduct of cGLP animal toxicity testing and/or IND applications.

Microbiological status of clean room controlled environments are evaluated by monitoring the culture of microorganisms in the lab working areas.

Levels of airborne particle contaminants are determined by monitoring the presence of number of particles to comply with federal standard 209E which requires 1 cfm for airborne particulate cleanliness. Met One Particle Counter model 237A is used to determine the particle counts in the lab.

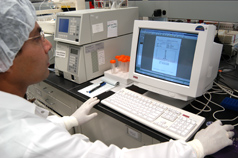

Solid Phase Peptide Synthesis (SPPS) is based on sequential addition of alpha-amino and side chain protected amino acid residues to an insoluble polymeric support. Briefly, synthesis is performed by stepwise addition of activated amino acids to the solid support (Wang resin and PEG-PS) starting from the carboxy terminus to the amino terminus. Activation of amino acids were performed by DIC-Oxyma chemistry. At the end of the synthesis the peptides were cleaved off the resin by reagent R ( 90% TFA, 5% Thioanisole, 3% Ethanedithiol, and 2% Anisole) and subjected to multiple ether extractions. The crude peptides were analyzed, characterized, and purified by Gel filtration (G-25 column), Reversed-Phase High Performance Liquid Chromatography (RP-HPLC, 486 and 600E by Waters Corporation) and later confirmed the correct mass by MALDI-TOF Mass Spectroscopy ( The Voyager-DE STR Biospectrometry Workstation).

Crude peptides are subjected to gel filtration followed by HPLC purification. HPLC purification is performed by the state-of-art HPLC system with Empower Chromatography Manager. The system is validated by authorized Waters validation specialist to comply with FDA standards. The purity of the peptide is confirmed by running analytical HPLC followed by mass spectrum analysis. The final purified peptides are vialed under aseptic conditions.